Market Background

With the continuous advancement of industry, cranes, as essential equipment for transportation and loading, are evolving towards larger scales, greater diversity, increased automation, higher speeds, and more complexity. Consequently, the demands on the main structure of cranes and their working environments are becoming increasingly stringent. Therefore, selecting the appropriate crane rail fixing method based on different structural forms and working environments is crucial for the safe operation of cranes.

In recent years, as the tonnage of cranes has increased and their operational frequency has risen, traditional rail fixing systems have become inadequate to meet the demands of the trend toward larger cranes. With the continuous evolution of design concepts, a novel rail fixing system—the flexible track fixing system—has gradually gained prominence across various industries.

Dalian ILLINO Group Co., Ltd. has achieved widespread application of its rail fixing systems in various sectors, including the quay cranes and yard cranes at container terminals both domestically and internationally, ship loaders and unloaders at ore terminals, bucket-wheel stacker-reclaimers, 900-ton gantry cranes in shipbuilding enterprises, coal terminals, grain terminals, bulk cargo terminals, and the metallurgical industry. The company's research and development team has established a long-term vision for the rail fixing systems, aiming to serve global ports and help customers achieve a once-and-for-all solution.

Product Features

Product advantages

1. High-Strength and Durable

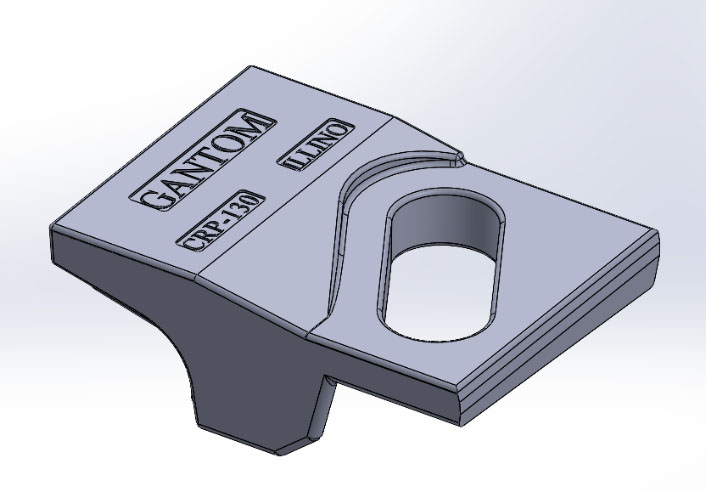

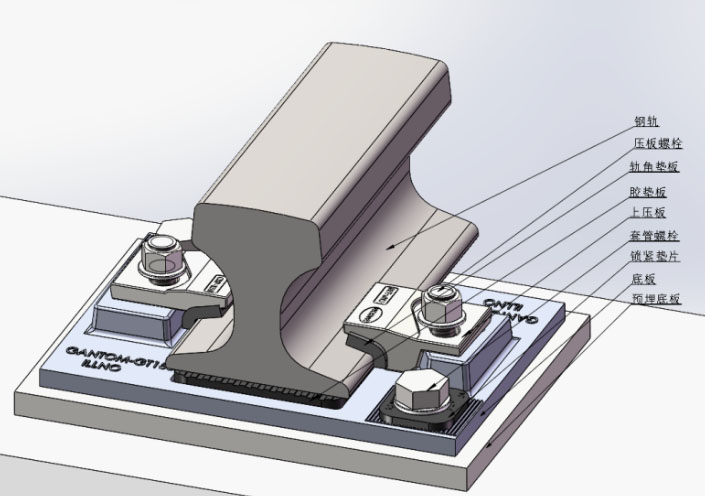

Utilizing premium materials and advanced manufacturing techniques, the upper pressure plate of the press plate assembly is forged from steel (cast products are prone to cracking and breaking), which imparts lateral flexibility to the rail and reduces vibration during equipment operation. The height of the rubber nose is shortened, thereby extending the service life of the upper pressure plate.

It boasts exceptional compression resistance and corrosion resistance, adapting to various complex environments to ensure long-term stable operation.

2. Longer Seamless Rail Welding:

The rail contact employs a full-angle upper pressure plate combined with a rail angle base plate to clasp the rail, utilizing a rail locking process characteristic (the friction of polymer materials is lower than that of rubber, offering the following advantages: ① protection of the rubber nose, ② enabling longer seamless rail welding, capable of achieving a single length of up to 1500 meters).

3. High Stability:

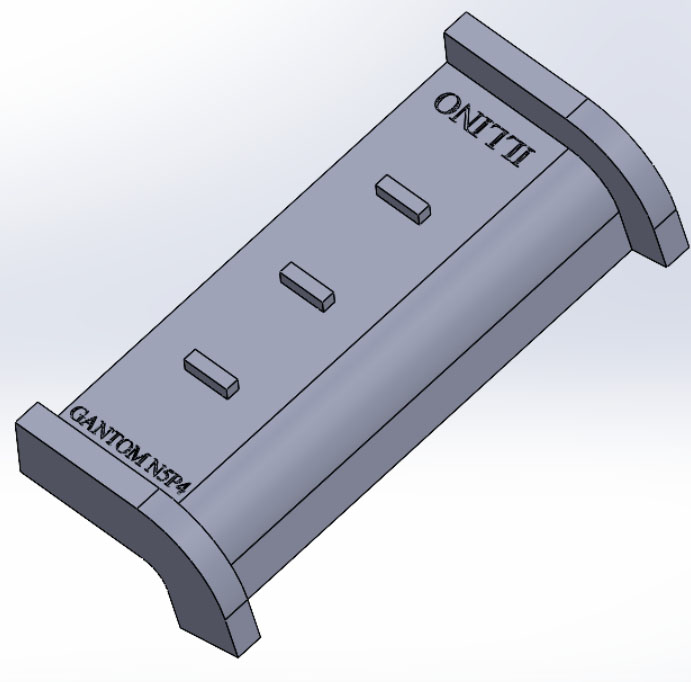

The embedded plate GANTOM-SP130/150-PA is made of high-performance PA66 nylon material, which allows for the timely release and elimination of resonance generated during the operation of the equipment on the track. (The new embedded base plate process design ensures that the contact and stress area of the base plate exceeds 90%, and the use of non-degradable materials effectively guarantees the stable performance of the product foundation. Each embedded plate is equipped with a mastic vent hole, effectively ensuring the control of on-site construction quality.)

4. Adjustable Elevation Changes:

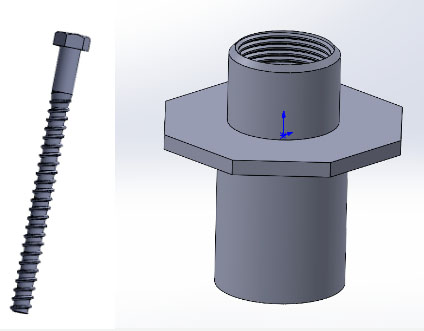

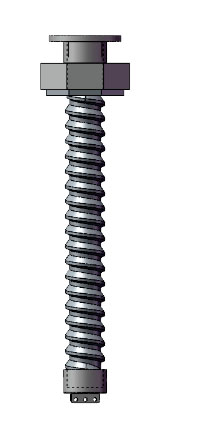

The embedded sleeve is made of high-performance nylon material, and in conjunction with the anti-loosening thread angle of the sleeve and sleeve bolt, it ensures that the tightened sleeve bolt will not loosen due to dynamic loads, simplifying and optimizing subsequent usage plans. The embedded sleeve, when used with an extended sleeve, can adjust for changes in elevation.

5. High Load-Bearing Capacity

The M30 sleeve bolt is made of 35CrMo material, with a tensile strength of ≥800Mpa, a standard tensile load-bearing capacity of ≥360KN, and a design tensile load-bearing capacity of ≥225KN; the shear strength is ≥640Mpa, with a standard shear load-bearing capacity of ≥320KN and a design shear load-bearing capacity of ≥200KN.

6. After-Sales Warranty

All materials come with a ten-year warranty. Should any performance issues arise with the materials within this period, our company will provide free replacements.

7. Passed Rigorous Testing

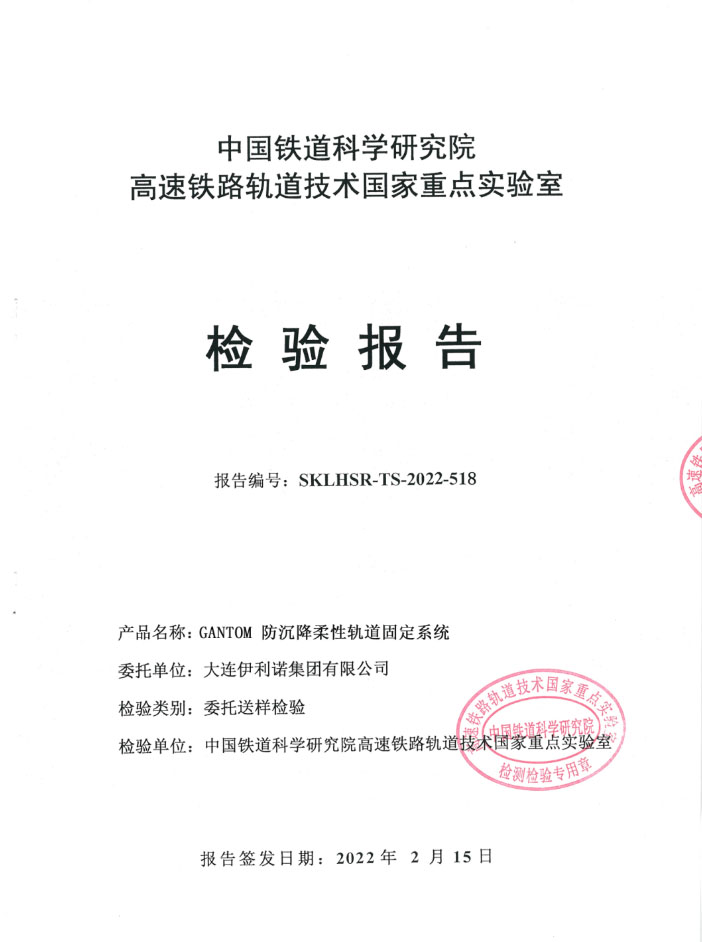

The products have been tested and have successfully met the 5 million anti-vibration tests at the Academy of Railway Sciences.

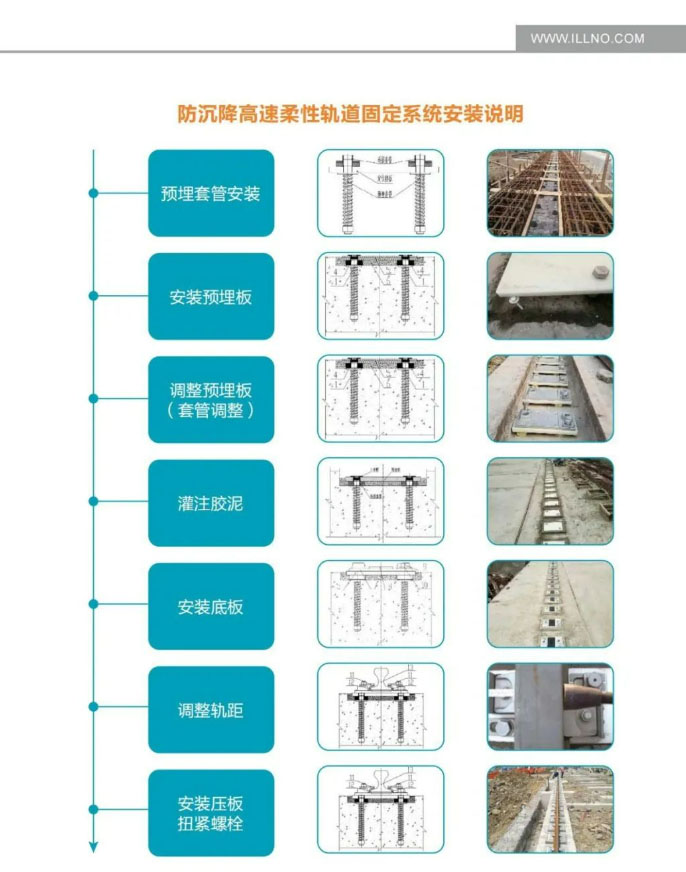

8. Precise Installation and Efficient Construction

With a modular design, the installation process is simplified, significantly reducing the construction cycle, lowering labor costs, and enhancing factory efficiency.