Chinese Intelligent Manufacturing Goes Global | ILLINO GROUP Warmly Congratulates the Completion ofthe Chancay Port Project in Peru!

On the evening of November 14th, Peru time, the Chair Man of China, Mr. Xi Jin Ping was in Peru for the APEC meeting, and Peruvian President Ms. Boluarte jointly attended the opening ceremony of the Chancay Port via video link from the Presidential Palace in Lima. The two heads of state issued the command to declare the port open. As a participant in the construction of this project, ILLINO GROUP feels deeply honored and proud to contribute to China's maritime Belt and Road strategy. The Chancay Port project in Peru is a key initiative under the Belt and Road cooperation between China and Peru. It is instrumental in helping Peru establish a comprehensive, diversified, and efficient connectivity framework that extends from the coast to the inland and from Peru to other countries in Latin America and the Caribbean. This project aims to create a "New Era Inca Trail" starting from Chancay Port, thereby driving the overall development and integration of Latin America and the Caribbean region.

"Intelligent Manufacturing" on the Crest of the Wave

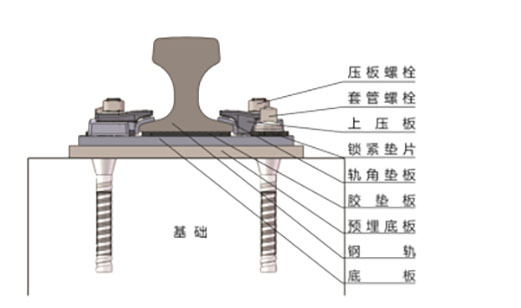

"Rail Fastening System" Sets a Chinese Benchmark

Chancay Port is located approximately 80 kilometers north of Lima, the capital of Peru. With a water depth of nearly 16 meters, Chancay Port stands as the only harbor on the Pacific coast of South America capable of accommodating mega-ships. The Chancay Port project officially commenced in June 2021, with its main construction encompassing 4 berths, 15 container yards, primary and secondary breakwaters, roads, and a comprehensive office area. The project is being constructed by a consortium of China Harbour Engineering Company Ltd. and CCCC Fourth Harbor Engineering Co., Ltd. Jiangmen Hangtong has primarily participated in the research and development, as well as the manufacturing, of the world's first highly intelligent, ultra-large self-moving pile-driving platform for this project.

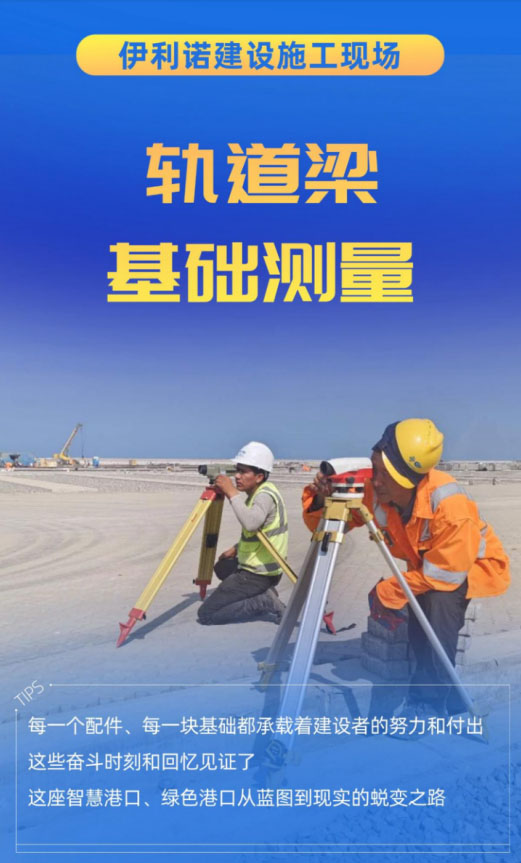

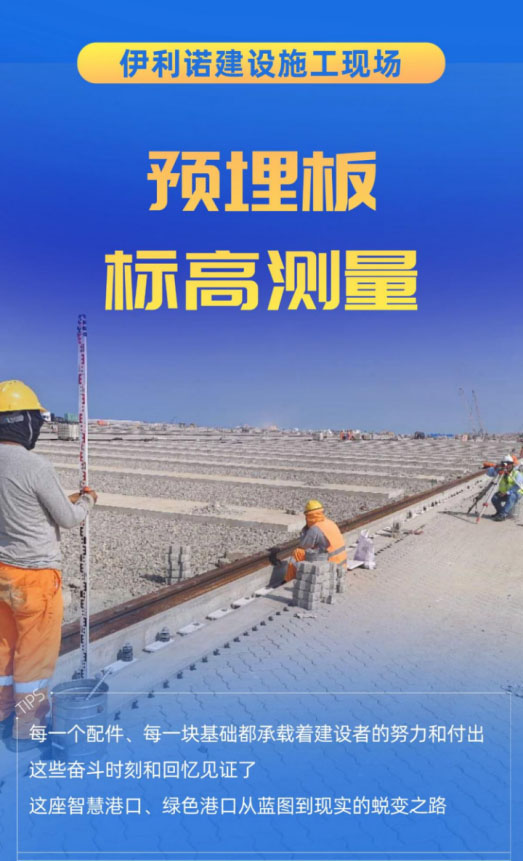

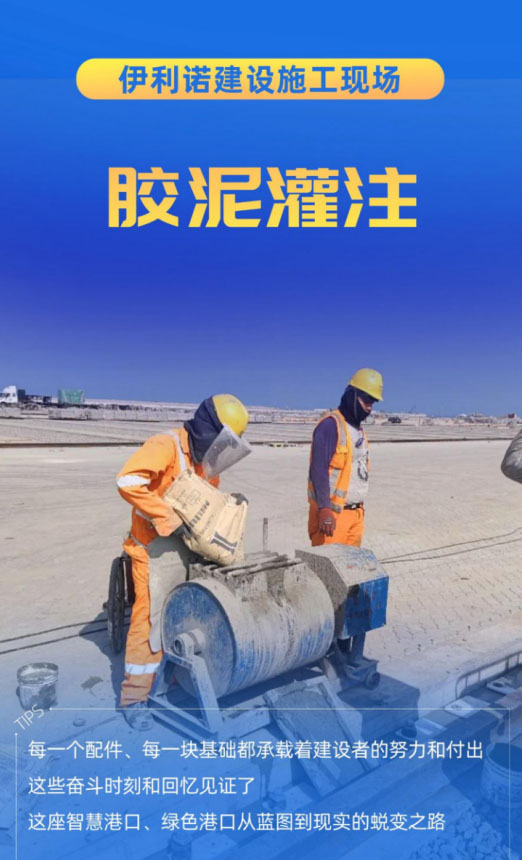

Located within the circum-Pacific seismic belt and subjected to the influence of ultra-long period waves and strong swells throughout the year, the construction waters of the project are perpetually beset by fierce winds and high waves. The exposed construction environment presents formidable challenges to the dock rail construction. In response to the on-site conditions, ILLINO GROUP has proactively developed and manufactured an "anti-settlement rail fastening system" to ensure the orderly and stable progression of the project. This system has garnered unanimous acclaim from the project owner, the supervision unit, and the project team during its application.

The rail construction project innovatively employs an anti-settlement rail fastening system, which is designed with a modular concept. This system effectively addresses a series of persistent issues that traditional solutions could not resolve, such as foundation settlement, the tearing of pressure plate rubber noses, and the failure of rail bottom rubber pads. It allows for rapid adjustment of foundation settlement and reduces rail maintenance costs.

Simultaneously, all components must not only meet the requirements for container transportation but also possess extremely high safety and stability, necessitating very stringent manufacturing precision. This presents significant challenges to the company's machining capabilities, welding and assembly standards, and deformation control.

ILLINO GROUP has addressed the challenges and focal points of rail fastening construction by formulating strategies, coordinating resources, closely monitoring the process, and strictly controlling quality. The company has made full use of the newly commissioned intelligent production lines and CNC machining equipment, focusing on production process management and precision control. Through the collective efforts of the team, all tens of thousands of components required for the equipment have been produced to standard and successfully assembled.

When it comes to the superior performance of the "Illinois Rail Fastening System," project leader Yu JianHai is well-versed in its merits. He stated that the Illinois anti-settlement rail fastening system features functions such as height adjustment, safety and reliability, and a long service life. It has been designed with full consideration of the foundational and operational characteristics of dock and yard rail systems. Not only does it provide a strong guarantee for the efficient operation of the project, but it is also simple to manufacture, easy to install, and saves time and effort in later maintenance and adjustments. It has set a Chinese benchmark in the process of building an important maritime hub port in South America.

Transnational Guardianship

The concept of "The Power of a Seed" permeates every phase of the project.

Chancay Port is the first smart and green port in South America. Its opening will reduce the maritime shipping time from Peru to Asian countries by at least 10 days, and the shipping time from Peru to China will be shortened to 23 days. More cargo ships from South American countries to Asia or the west coast of the United States will no longer need to squeeze through the Panama Canal or detour around the southernmost tip of South America, which will have a positive impact on global economic and cultural exchanges.

In recent years, ILLINO GROUP has actively 'gone global' in alignment with the 'Belt and Road' initiative, leveraging its own advantages to construct and deliver hundreds of port rail fastening system projects for various countries and regions around the world. Additionally, it has participated in engineering projects in 'Belt and Road' partner countries such as Peru, Thailand, Singapore, and India.

Moving forward, ILLINO GROUP will continue to deeply implement the strategies of 'Manufacturing Power' and 'Maritime Power', dedicating itself to contributing the strength of Chinese intelligent manufacturing to the high-quality development of national marine engineering equipment research and manufacturing.